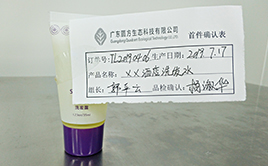

The cosmetics workshop covers an area of about 1000 square meters. The main operations include: package disinfection, ingredients, emulsification, static, micro inspection, filling, first article confirmation and final finished product inspection.

Our products include body wash, shampoo, lotion, conditioner and other general liquid and cream liquid. The semi-automatic equipment applied in the workshop includes the semi-automatic filling machine in the semi-automatic filling area, the dc638 full-automatic hose filling and sealing machine in the full-automatic filling area, the emulsion pan, the mixing pan, the ultra-pure water bucket and the self water bucket as well as the white and black inkjet printer in the outsourcing area. Our production environment, safety and health, strictly control the quality management of each section and meet the production standards certified by ISO22716, GMPC and green leaf.