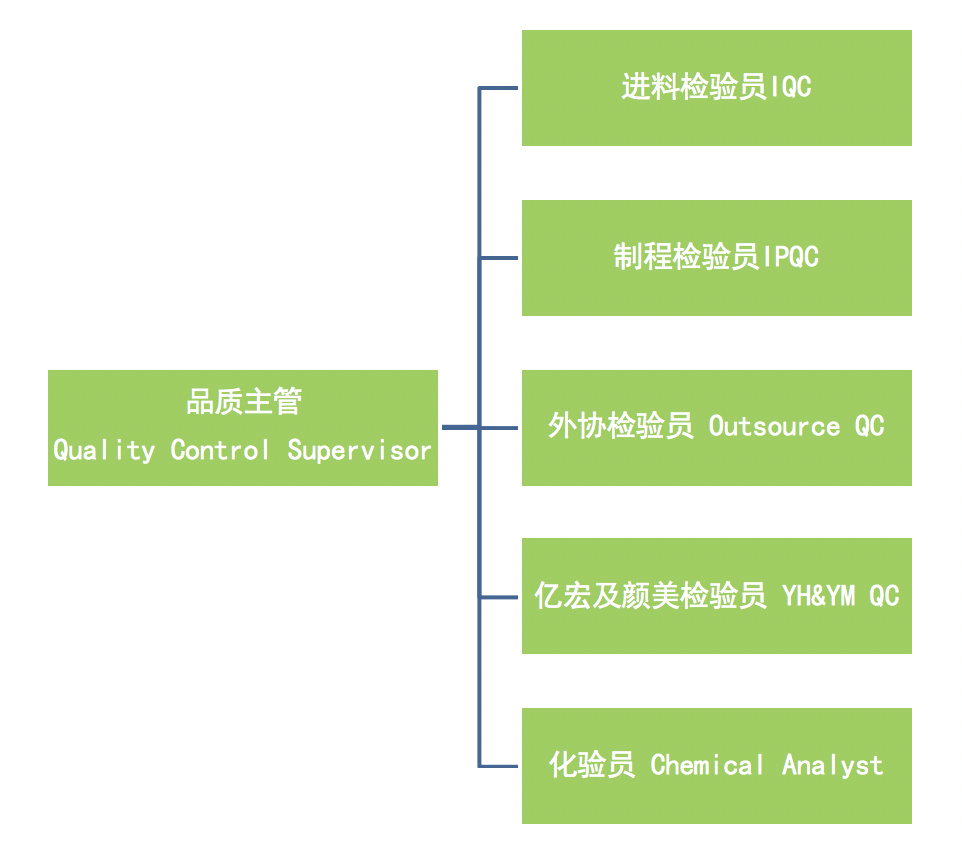

The quality control department covers an area of about 150 square meters, and its main work includes:

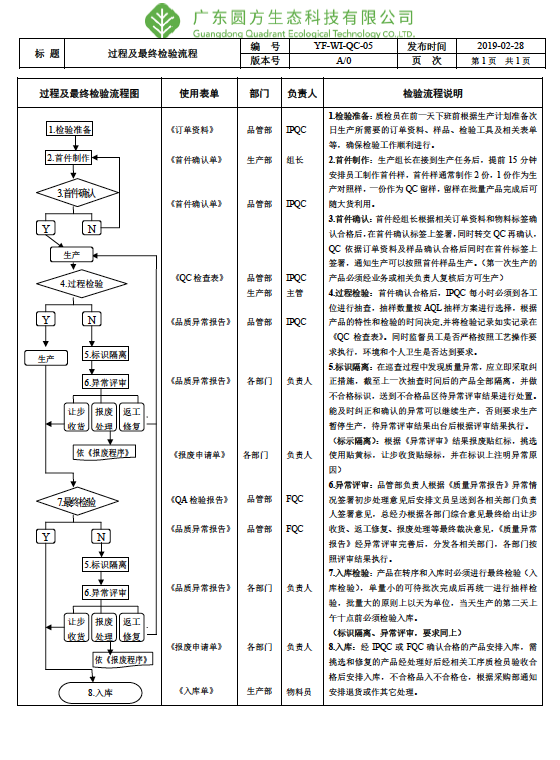

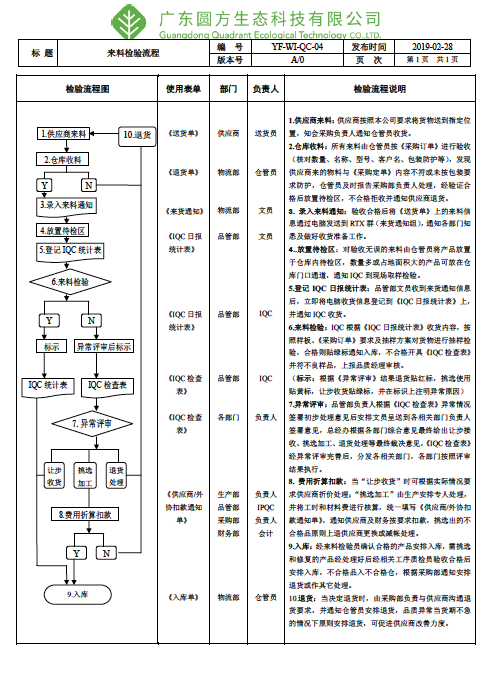

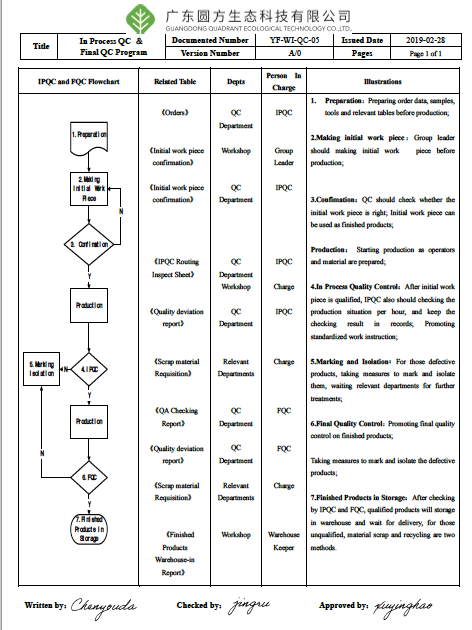

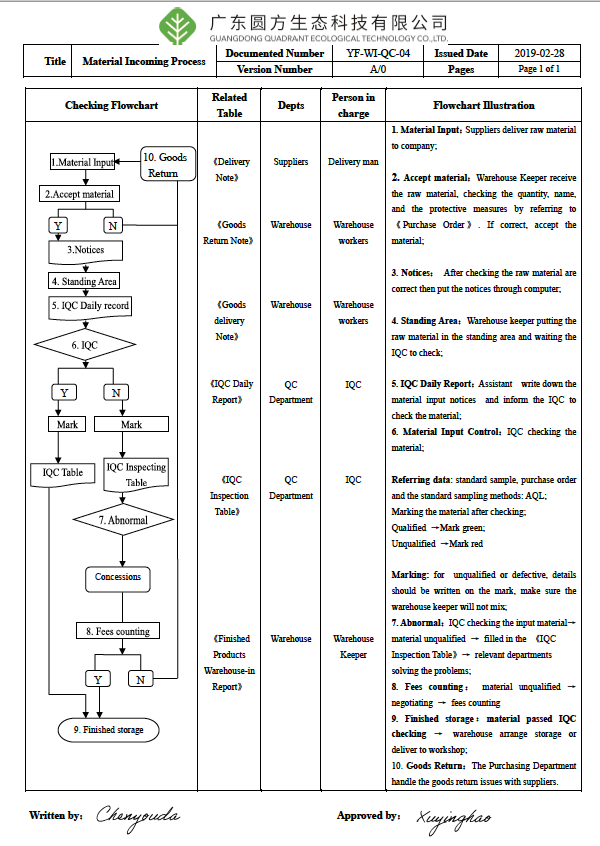

1. Incoming inspection, process inspection and finished product inspection

2. Microbiological and physical and chemical inspection of finished and semi-finished products (including chemical raw materials, contact surfaces, human hands, packaging materials and water)

3. Preparation of product operation instructions, key process operation instructions, inspection key and other guidance documents

4. Handling of workshop abnormalities and customer complaints

5. Quality analysis

The test equipment includes packaging material testing instrument (seal tester, push pull meter, torsion meter, vernier caliper, micrometer), content testing instrument (viscometer, conductivity meter, pH acidity meter, magnetic stirrer, super constant temperature water bath pot, digital display constant temperature water bath pot, electric heating blast drying box, low-speed centrifuge, constant temperature and humidity box, disinfection cabinet, electronic balance, electronic analysis day Flat, fridge, super clean workbench, vertical pressure steam sterilizer, biochemical incubator, mold incubator, Abbe refractometer, foam meter and other equipment.

We strictly control the quality management of incoming materials, semi-finished products, finished products and all links in the production process, and meet the certification standards and customer requirements of GMPC, ISO 22716, RSPO, FFC.