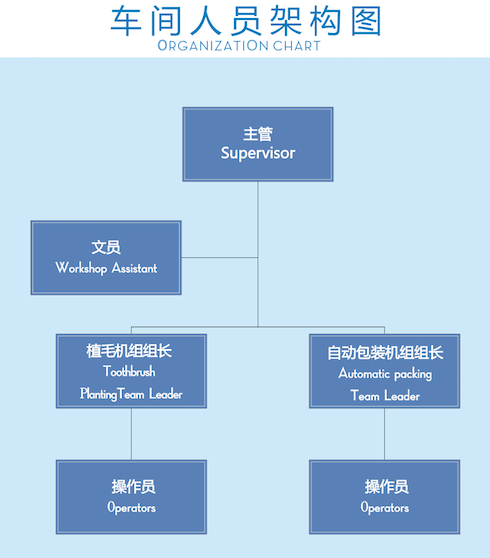

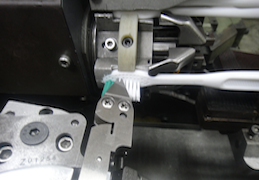

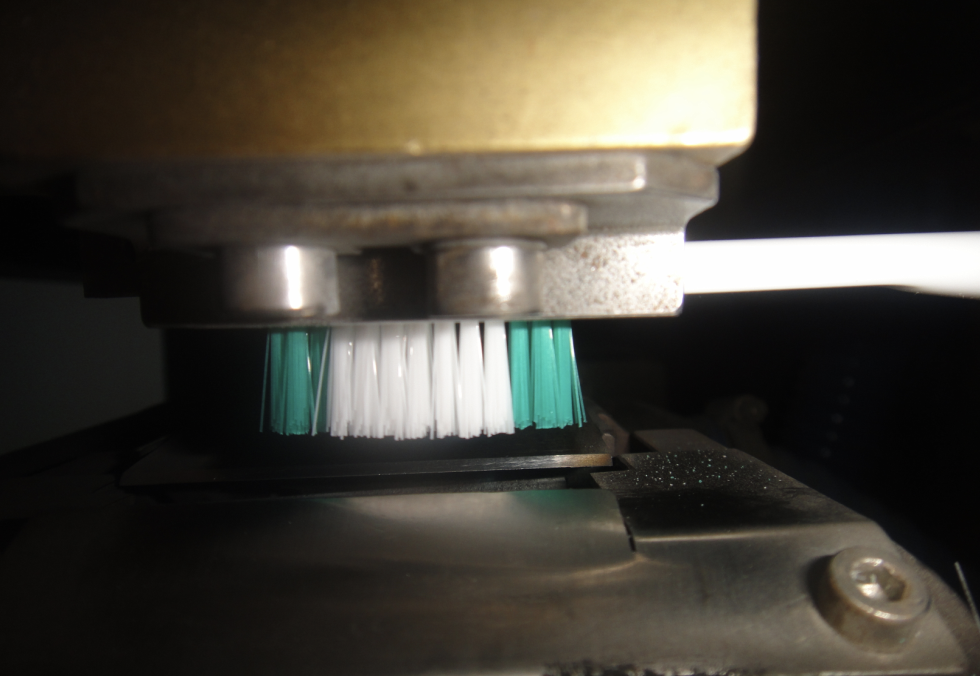

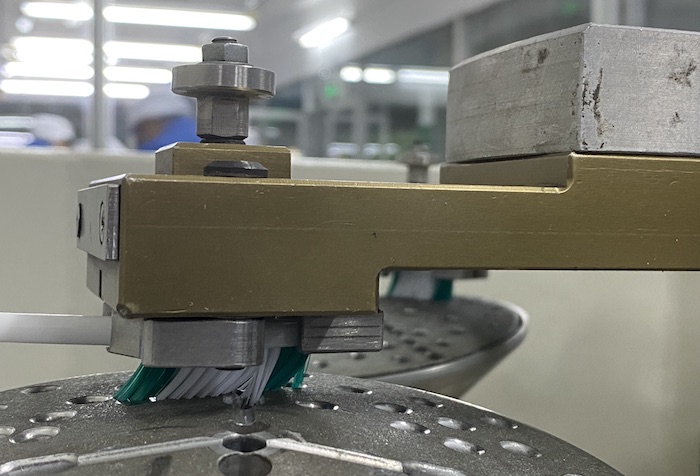

The toothbrush workshop covers an area of about 500 square meters. The main tasks include hair planting, cutting, sanding and dedusting as well as final quality inspection. The main products are Swiss toothbrush and other series of toothbrushes will be produced in the future. The equipment applied in the workshop includes the intelligent speed control high-speed hair planting machine and the hair grinding machine in the toothbrush planting and grinding area; the multifunctional pillow type packaging machine in the toothbrush packaging area and the labeling machine in the labeling area. Our production environment ensures quality, safety and health, we strictly control the quality management of each section, in line with the FDA certified production standards.