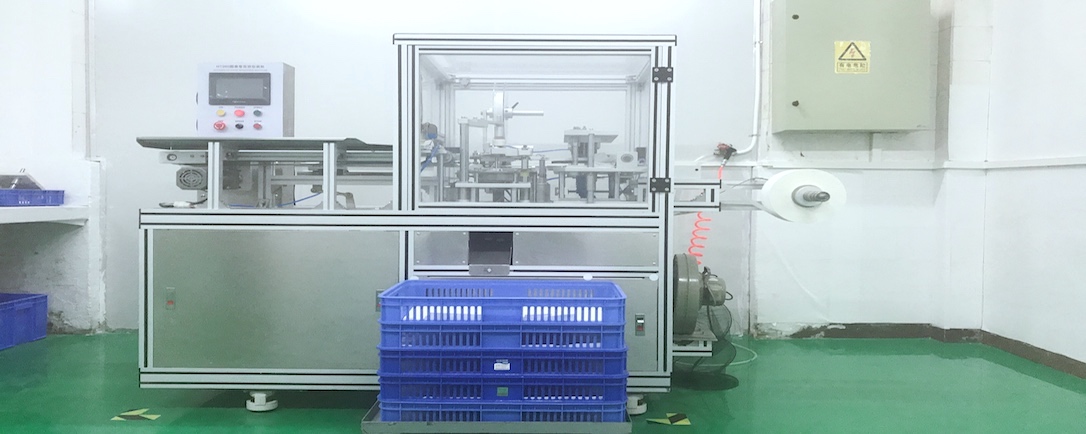

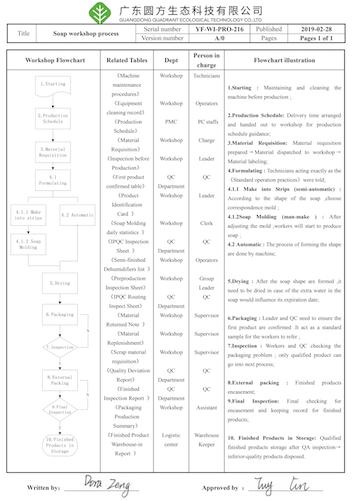

The soap workshop covers an area of about 450 square meters. The main tasks include ingredients compounding, mixing, grinding, soap striping, soap washing and final dehumidification. The main products include soap and handmade soap. The equipment used in soap workshop includes automatic packaging machine in packaging area, pleating machine, code spraying machine and automatic soap washing machine in soap washing area. Our production environment, safety and health, strictly control the quality management of each link, and meet the production standards certified by iso22716, GMPC, RSPO and green leaf.