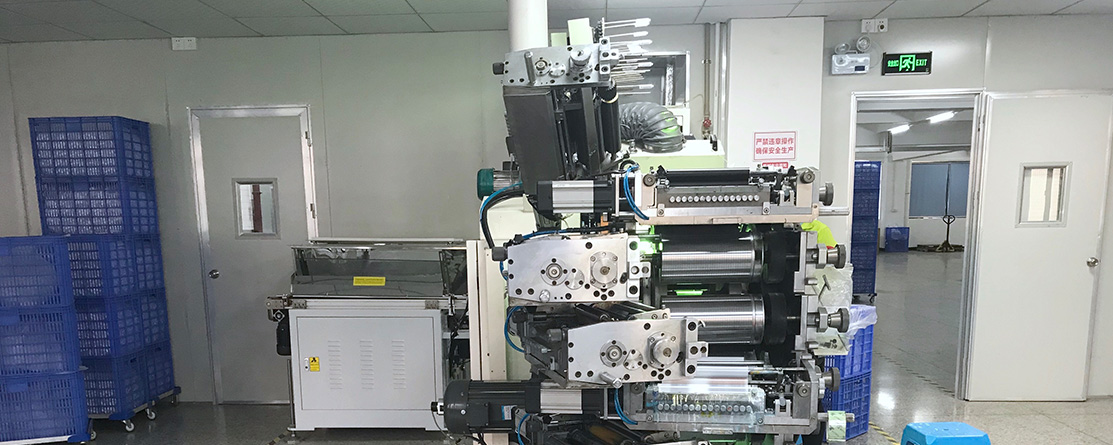

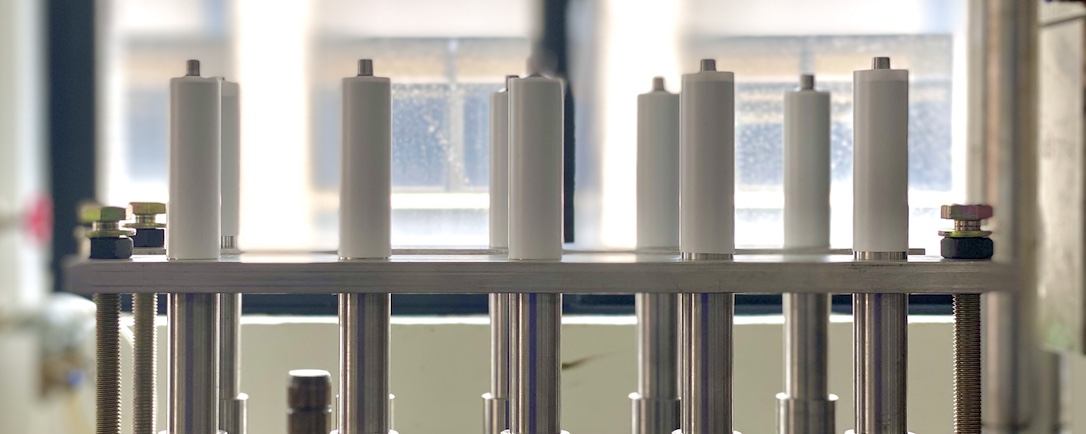

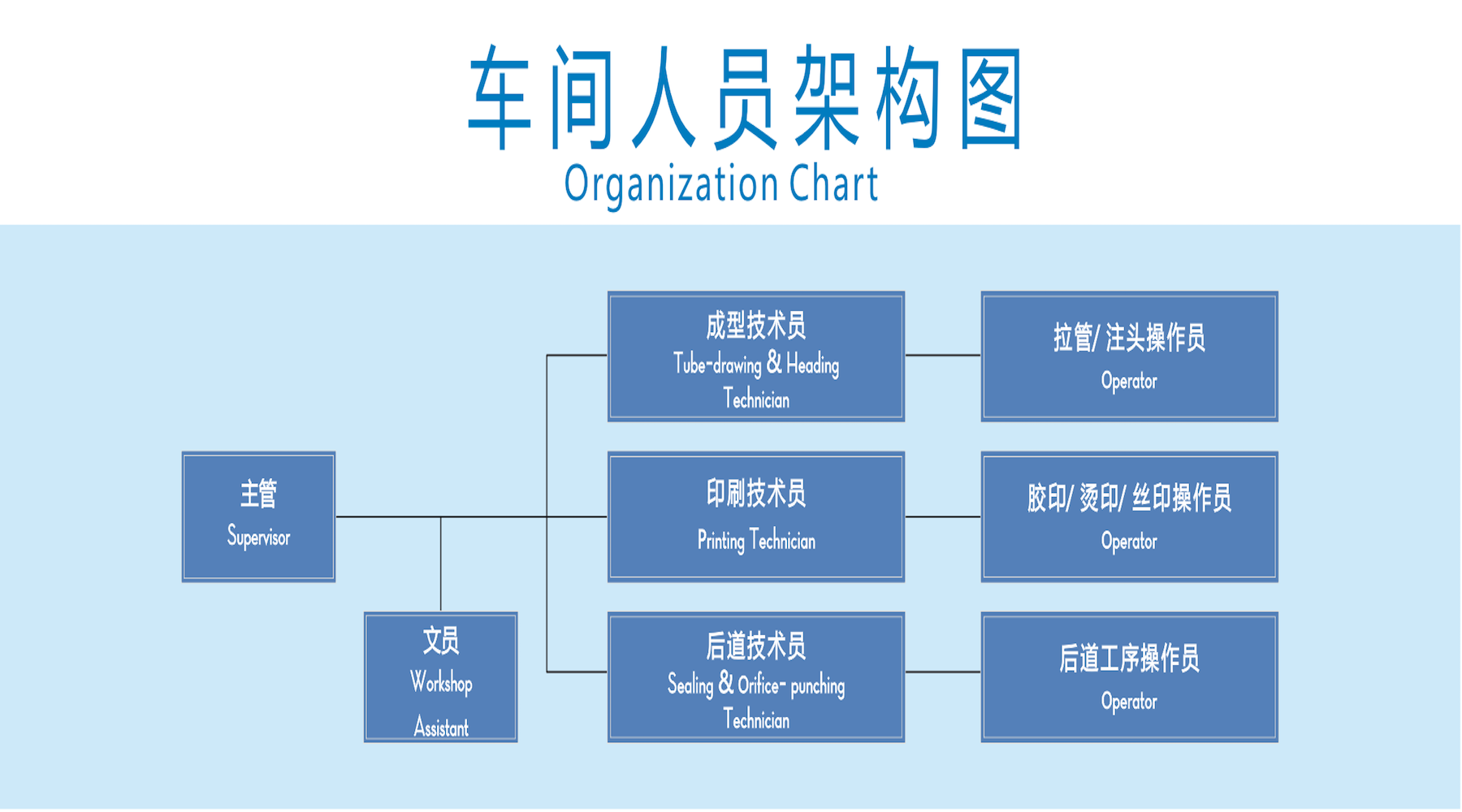

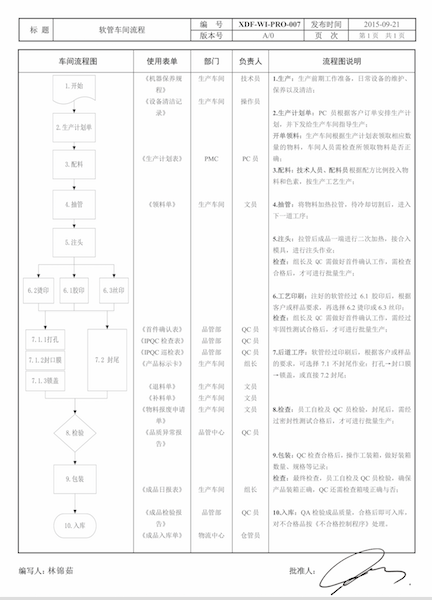

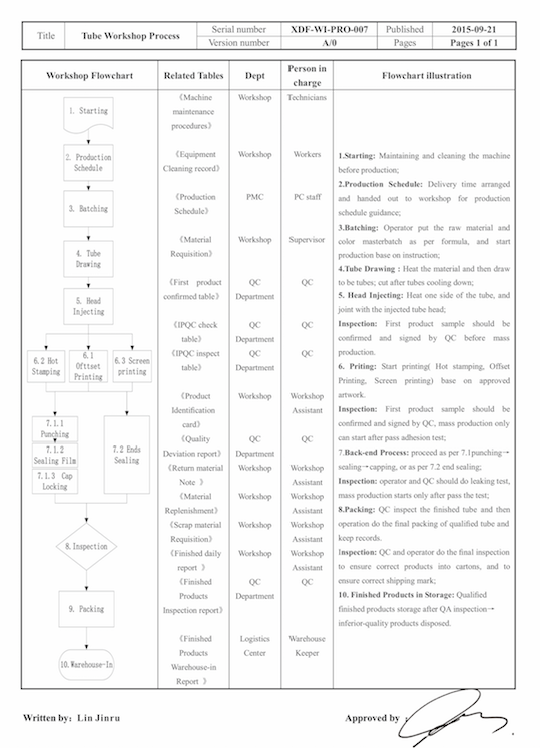

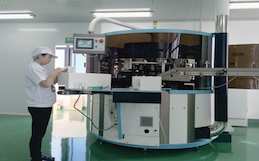

The Tube workshop covers an area of approximately 1000 square meters. The main operations include pipe drawing, injection head, offset printing, silk screen printing, stamping box sealing and lock cover. The main product is PE tube. The application equipment in the workshop includes the semi-automatic injection head machine in the Injection ead room, the automatic tube drawing machine in the Tube drawing room, the precision full-automatic six-color offset press in the Offset room, the automatic silk screen machine in the Silk screen room and the full-automatic punching and locking cover capper in the Tube processing room. Our production environment is safe and healthy, we strictly control the quality management of all section in accordance with ISO22716, GMPC certification standards.